Prerequisites

Plasticized PVC compounds have a wide variety of formulations. If you have little knowledge about PVC, please read the article on PVC types and applications.

After selecting the PVC type (E or S), choosing the correct plasticizer for each application is the most crucial parameter to achieve the best formulation.

Choosing Plasticizer

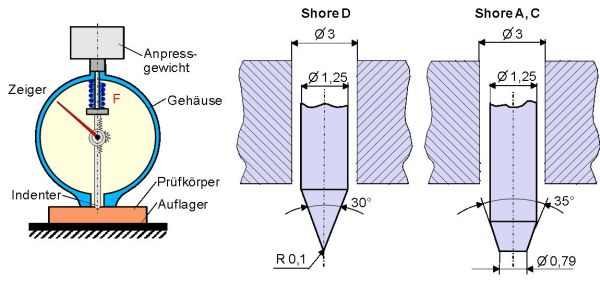

Whenever a plasticizer is used in PVC formulation, the final product will have more flexible and rubbery properties than un-plasticized PVC. The Shore A is a parameter used to measure and determine the hardness of plasticized PVC. Usually, Shore A ranges between 0 to 100. A lower Shore A indicates a more flexible product.

The substitute factor (SF) is a parameter that helps us compare each type of plasticizer with DOP, which is the reference plasticizer. If the SF is higher than 1, it means that in order to achieve the same Shore A as DOP, you will need to add more plasticizer than the amount of DOP to reach the same Shore A. For example, epoxidized soybean oil SF is 1.1, which means you will need to add 10% more plasticizer to gain the same flexibility as DOP.

In addition to flexibility, plasticizers can add other properties to the final product. Some plasticizers are suitable for low-temperature environments (DOA is suitable for environments below 10˚C), while TOTM is better for improving flame retardancy. Ultimately, when choosing the right plasticizer for PVC formulation, the flexibility of the final product, SF, and the final product’s properties and usage environment should be taken into consideration.

۱۲ Comments. Leave new

سلام واقعا عالی بود

پستای بیشتری بزارید

سلام واقعا عالی بود

واقعا خوشم اومد

خیلی سایتتون مطالباش خوبه

ممنون

پستای بیشتری بزارید

جشم حتما، مطالب در حال آماده شدن هست کم کم اضافه میکنیم

واقعا خوشم اومد

واقعا حال کردم

ممنون از مطالبتون

thanks for providing useful information o plasticized pvc compound and formulation